Concrete Printing

I was introduced to the world of Concrete Printing through the LefLab that is organised by ICE Cube at Thomas More. The provide opportunities for interdisciplinary teams to work together and create truly wonderful things. The goal of this project was to improve the existing facility and functionalities of the Cobod Concrete Printer that was now stationed at Kamp C in Westerlo. These improvements, together with a solid business plan, would provide an opportunity to bring this technology to the campus and open new doors for future students.

Slicer software

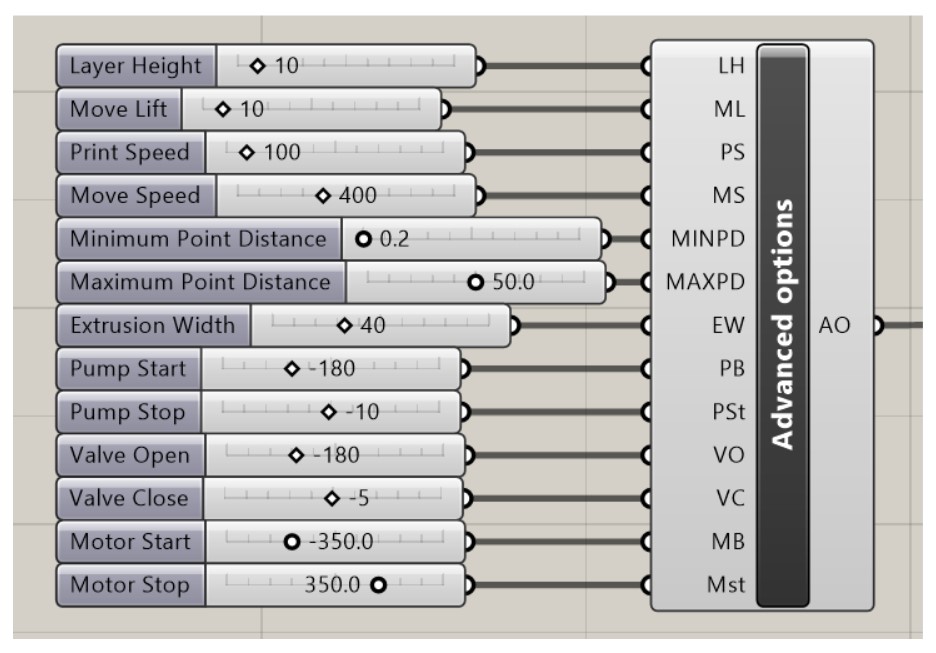

During the first semester of academic year 2021-2022, two other students had already participated in this project and created the foundation for slicer software that the printer could use. Because of the research done by other teams on the hardware of the printer, a custom slicer software was needed that was seemlessly integrated into the new technologies.

We expanded upon the slicer software that was created in the GrassHopper plugin that comes with the 3D rendering software "Rhinoceros3D". For this we needed to understand the concepts of lines, arcs, polylines and other geometric entities, especially how these behaved on a code level. Using the RhinoCommon SDK and Visual Studio we started exploring the language of C#.

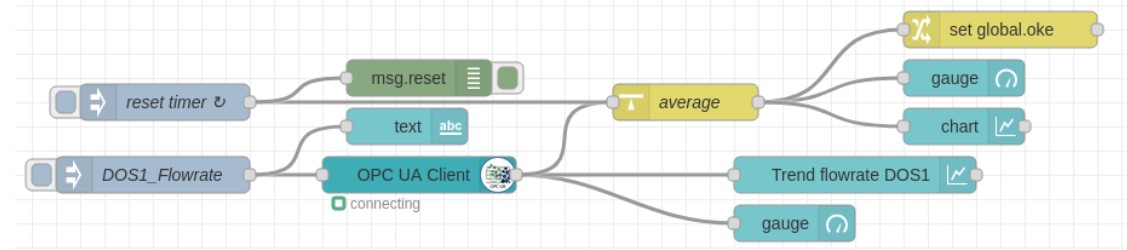

Node Red Visualisation

Apart from the actual slicing software, we also made improvements on data logging and visualisation. This is still a work in progress and will surely be continued next year. The idea is to simplify reports and make more improvements on the printing process using the knowledge gathered from the historical data.

G-code and Valve

The biggest challenge for this project wast to allow the newly implemented valve on the extruder to respond to the gcode that was generated by the slicer software. Opening and closing the valve needed to be timed and placed between the regular commands of extrusion and movement.